Anywhere you’re producing aggregates, you’ll have plenty of large heavy equipment to maintain.

And that means many technicians needing safe ascent and access to elevated parts of various machines. Whether it’s maintenance for a Hauler, Excavator, Dozer, or anything else, the Employer will likely have two main goals in mind…1 being worker safety, and 2 being reduced downtime.

These goals are great to have, but not so easy to achieve. Usually, one will mitigate against the other. You can find a faster method that’s not really safe enough, or a safe method that’s slow and cumbersome.

This means that there is a commercial pressure to cut the safety corners and unfortunately some companies take what looks like the easy way and forgo the safety. That’s like a game of Russian Roulette, and those that have to hold the Pistol are the Employees. Little wonder that this becomes an extremely expensive approach when an incident happens, but even if no incidents occur, the Employee carrying the risk of life altering injuries will not be a happy Employee for the long term. Job dissatisfaction can set in, and Employee turnover results in costly re training etc.

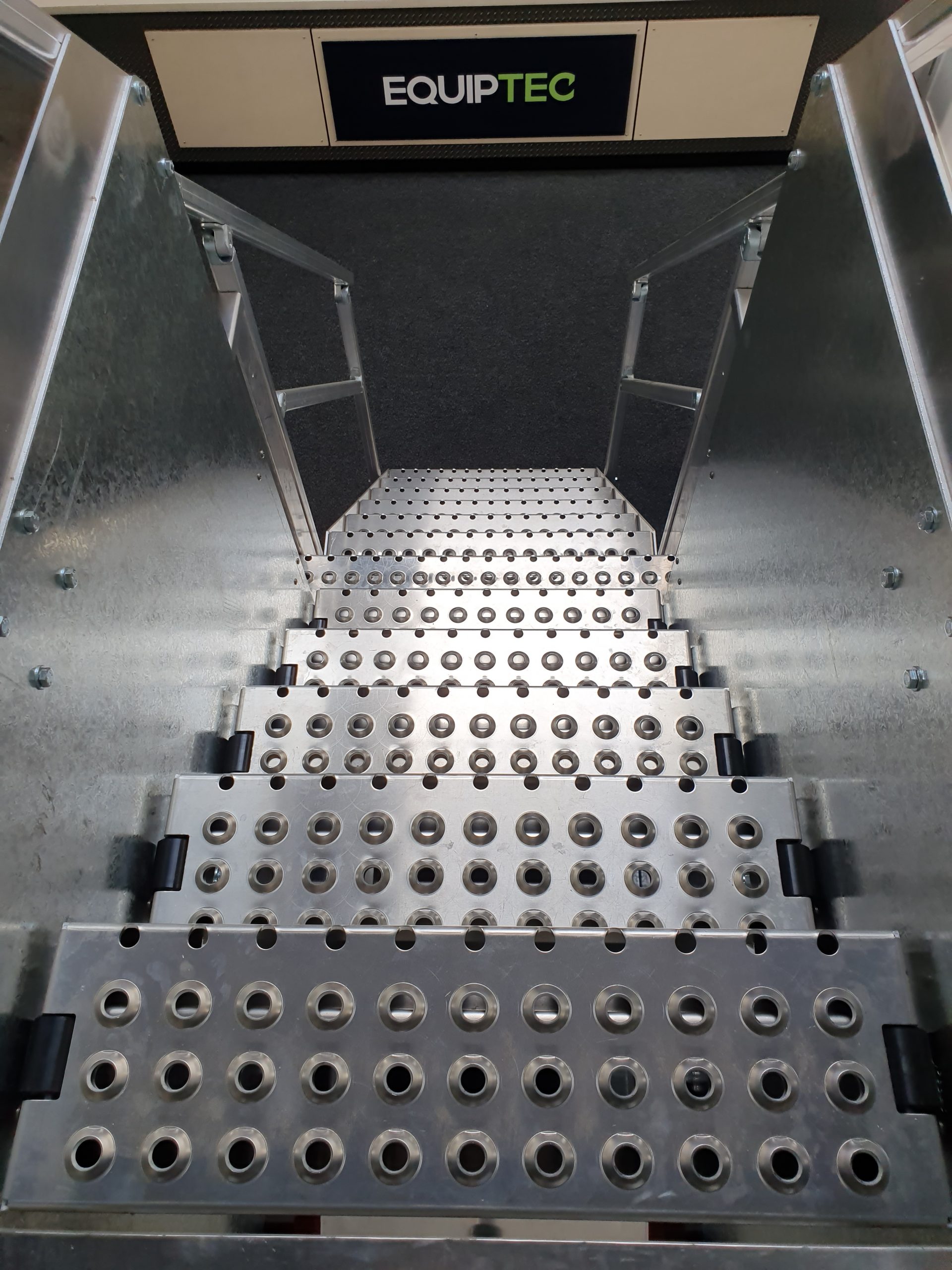

The other way is a lot better for the long term. Fitting out your Employees with the gear they need to get the job done Safely, Quickly AND as easy as possible is a sure-fire way to earn their appreciation. What’s so good about that is that their appreciation will usually result in loyalty. When they see they are working with the best of the best equipment, they feel the solid platform under their feet, at the right height for the job on hand, they know they will be going home to their families safe that night, they won’t want to work anywhere else.

This loyalty is priceless for your operation. We all know that our Team is our single most valuable asset, and getting them behind you like this, coupled with the worlds best low-level access system, will produce some amazing results. Here is an example;

A West Australian Mine used Scissor Lifts to access the rear of their Dump Truck tubs for a process that they needed to do very regularly. The Team saw the AHP advantage and asked Equiptec for an extra-large unit to take the place of their Scissor Lifts. This unit not only provided access, but also a barrier to prevent workers from falling off the rear edge of the tub. After 4 years of use, the Team sent photos to the Distributor involved. The AHP was still going strong, and they proudly commented it was “still saving us cost & downtime. What used to take 4 people 6 hours, now takes 2 people to get the job done in 3 hours”.

Not only was this a 75% saving in labour, but it also shaved 50% off the downtime of that expensive Dump Truck. Everyone wins…a proud, happy , safe team are working super efficiently and producing awesome savings for the company.

Equiptec AHP made the difference here, and maybe it can in your operation too? Call now to discuss the endless possibilities!